Stock Conversion Suggestions

In TRASER DMS 365, you have the option to use a worksheet for stock conversion. This worksheet supports you in developing suitable inventory management strategies for the various stages of the product lifecycle and in proposing the corresponding changes to the stockkeeping units. The worksheet analyzes how many items were sold within a defined period and, based on this data, generates suggestions for the quantities that should be stocked in the future. This allows the inventory to be classified based on its movement frequency and level of utilization. The generated suggestions are displayed in the worksheet. You can review these suggestions, adjust them if necessary, and then execute the process to carry out the stocking accordingly. This chapter contains all essential information regarding the setup and use of the stock conversion functionality and is divided into the following sections:

- Setting up Stock Conversion

- Setting up Stock Conversion Templates

- Setting up Stock Conversion for Stockkeeping Units

- Executing Stock Conversion Suggestion Worksheet

Setting up Stock Conversion

Before you can receive suggestions on item stocking, some basic settings must first be configured, such as the setup of the stock conversion. You can store the stock conversion setup on the stockkeeping units, which sets up the basic parameters for dynamic stocking. Proceed as follows to set up stock conversion:

- Use the quick search (ALT+Q) to find the Stock Conversions page.

- To create a new stock conversion card, click New in the menu bar.

- In the General FastTab, enter a unique code in the Code field.

- In the General FastTab, enter a unique description in the Description field.

- In the General FastTab, specify the period in the Dead Stock Conversion Period field that should be used to assess an item’s demand activity. If there is no demand for the item within this period, it is classified as dead stock. Enter negative values to specify the period retrospectively, for example, -6M for the past 6 months or -1Y for the past year.

- Navigate to the Details tab.

- In the Base column, choose from the dropdown menu the criterion that will be used for the stock conversion. When base is set to Call, the system checks how frequently an item has been used in sales orders. It does not take the exact quantities into account, but only counts the number of order lines containing the item. When base is set to Quantity, the system evaluates the actual quantity of items ordered in sales orders.

- In the Value column, specify the threshold applied to determine the stock conversion. Items above this threshold are classified as active stock, while items below the threshold are classified as semi-active stock. For example, enter the value 3 if an item should be considered for dynamic stocking after appearing in three calls. If the base is Quantity, entering 3 means that the item will be used in dynamic stocking once three units have been sold.

- Your entries are saved automatically.

You have successfully set up stock conversion. The next section describes how to set up stock conversion templates.

Setting up Stock Conversion Templates

Before you can receive suggestions on item stocking, some basic settings must first be configured, such as the setup of the stock conversion templates. You can store the stock conversion template on the stockkeeping units, which specifies the general calculation logic used for inventory value planning and stocking. Proceed as follows to set up stock conversion templates:

- Use the quick search (ALT+Q) to find the Stocking Templates page.

- To create a new stocking template, click New in the menu bar.

- Navigate to the General FastTab and fill in the fields according to the following table:

| Option | Description |

|---|---|

| Code | Enter a significant code for the stocking template. |

| Description | Enter a clear description for the stocking template. |

| Calculation Method | Choose the method to be used for calculating optimal stock levels, such as Average Daily Demand. During the calculation of stocking quantities in the stock conversion suggestion worksheet, the system takes into account the average number of units sold per day for an item. |

| Min Value is | Select whether the stock conversion suggestion worksheet should consider the safety stock or the reorder point when performing calculations. |

| Rounding Method | Select the rounding method to be applied during the calculation to ensure practical stocking quantities. |

| Sales History Calculation Period | Specify the look-back period for analyzing sales data which will be used to calculate the average daily demand and stock quantities. Enter negative values, for example, -6M for the past 6 months or -1Y for the past year. The value in this field should match the value in the Dead Stock Conversion Period field, which you set up in the Setting up Stock Conversion section. |

- Your entries are saved automatically.

You have successfully set up a stocking template. Via the template, you can also configure the matrix rows and columns and the matrix layout to specify the stock conversion in detail. The individual options are explained in the following subsections.

Creating Matrix Rows

The matrix rows allow you to define a tiering that determines the point at which a new level is reached based on an item’s unit cost. This controls whether higher-priced items are stocked in the same way as lower-priced items. Proceed as follows to set up the matrix rows:

- To do so, click on Matrix Rows in the menu bar of the stocking template card.

- In the Unit Cost field, specify the item’s initial price. Repeat this step for additional price values to establish a tiered pricing structure.

- Your entries are saved automatically.

You have successfully created a tiered pricing structure using the matrix rows. The next subsection describes how to set up the matrix columns:

Creating Matrix Columns

Using the matrix columns, you define a tier that determines the activity value. This activity value, in turn, defines the tier for the base field, which you set up in the Setting up Stock Conversion section. This tiering is applied either to the number of calls or to the exact quantity of items. Please proceed as follows to create the matrix columns:

- Click on Matrix Columns in the menu bar of the stocking template card.

- In the Activity Value field, enter a starting value, for example 5, if the stock conversion should be applied after 5 calls or a quantity of 5 items. Repeat this step for all additional values to establish the desired tiering for the base of the stock conversion.

- Your entries are saved automatically.

You have successfully created a tiering of the stock conversion base using the matrix columns. The next subsection describes how to configure the stock conversion matrix via the matrix view.

Setting up Matrix

After you have created and defined the matrix rows and columns, you must then set up the matrix. The matrix is used in the stock conversion suggestion worksheet to determine into which row and column an item will be placed. The assignment depends on the configuration and is based on the relevant calls or quantities within the period defined in the stocking template. To set up the matrix, proceed as follows:

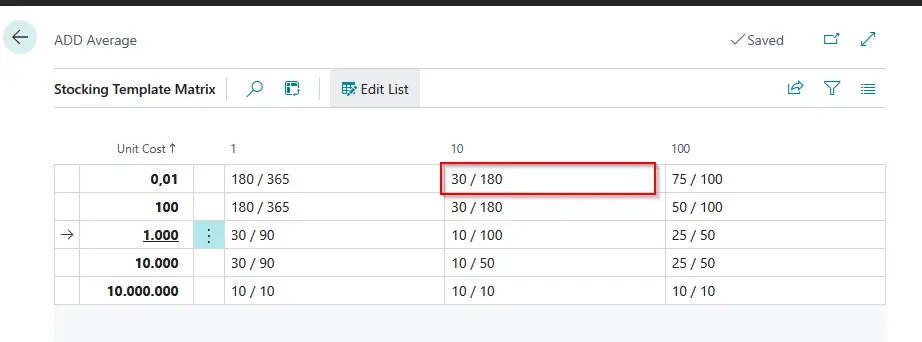

- In the menu bar of the open stocking template, click Matrix View. The matrix displays the previously defined price ranges in the rows and the corresponding activity values in the columns.

- Enter the desired values in the matrix according to your individual requirements. Below is an example:

Example

You have an item that uses the Average Daily Demand calculation method, as set up in the stocking template.

- The item costs €25.

- The time period defined for the Sales History Calculation Period is 1 year.

- The sales (calls) in the past year amount to 12.

This results in an average daily demand of approximately 12/365, or about 0.03 units per day. Next, the item is assigned to the appropriate position in the matrix:

- Unit Cost €25 → Row 0.01 (since the price is below €100).

- Activity value 10 calls → Column 10 (since the number of calls is below 100).

The corresponding cell in the matrix is 30 / 180. These two values are used as multipliers.

- The first value, 30, represents the minimum or safety stock, depending on the setting of the Min Value Is field in the stocking template.

- The second value, 180, represents the maximum inventory.

These factors are multiplied by the average daily demand (0.03), resulting in the following new stock conversion suggestions:

- New minimum stock → approximately 0.99 units (this value will be rounded up and therefore corresponds to 1 item, provided that an appropriate rounding method has been defined in the Setting up Stock Conversion Templates section)

- New maximum stock → approximately 5.92 units (this value will be rounded up and therefore corresponds to 6 item, provided that an appropriate rounding method has been defined in the Setting up Stock Conversion Templates section)

These calculated values would then be proposed for the item in the stock conversion suggestion worksheet. Once you have set up the matrix according to your needs using this example, the setup process for the stocking template is complete. The next section describes how to set up the stock conversion for stockkeeping units.

Setting up Stock Conversion for Stockkeeping Units

To apply the settings configured in the previous sections to the stockkeeping units, proceed as follows:

- Use the quick search (ALT+Q) to find the Stockkeeping Unit Setup page.

- Navigate to the Stock Conversion Code column in an existing line and enter a code that you previously created in the Setting up Stock Conversion section.

- Navigate to the Stocking Template Code column in an existing line and enter a code that you previously created in the Setting up Stock Conversion Templates section.

- Then, in the Stocking Method column, choose the desired stocking method from the dropdown menu. You can choose between the following options:

| Option | Description |

|---|---|

| Non-Stocked | This category includes items that are being ordered for the first time or are not typically stocked, for example, new products or special individual orders. These items are excluded from stock planning. |

| Manual | This category includes items that are intentionally not subject to automatic stocking, for example, service vehicles or special components acquired on a demand basis. For these items, no calculation of minimum or maximum stock is performed. |

| Dynamic Stock | This category includes items relevant to stock conversion. The system automatically determines reorder points and maximum stock levels, ensuring optimal inventory management. |

| Dead Stock | This category includes items that are no longer in demand or required. Stock replenishment is not required, as there is no longer any demand for these products. |

| Semi-Active Stock | This category includes items that are procured but only partially meet the requirements for dynamic stocking. |

- Your entries are saved automatically.

You have successfully set up the stock conversion information. In the next step, specific stockkeeping data for the items must be created. To do so, please proceed as follows:

- Use the quick search (ALT+Q) to find the page Create Stockkeeping Unit.

- A dialog window indicates that the stockkeeping unit data will be created based on the values previously configured. Click Yes to confirm.

- The stockkeeping unit data is generated automatically.

You have successfully created stockkeeping units for items. The stock conversion details are now displayed in the Planning FastTab on the stockkeeping unit card within the corresponding stock conversion fields. The setup is complete. The next section describes how to execute the stock conversion suggestion worksheet to trigger inventory replenishment.

Executing Stock Conversion Suggestion Worksheet

After completing all required settings for stock conversion, you can populate the stock conversion suggestion worksheet and then execute it. The worksheet uses the configured matrix settings to determine item sales within the defined period and, based on this data, generates suggestions for the optimal stock quantities to be replenished. Please proceed as follows to fill in and execute the stock conversion suggestion worksheet:

Note

Please note that only items with a creation date are considered. Therefore only items created after the feature was introduced will be taken into account, as the creation date cannot be added retroactively.

- Use the quick search (ALT+Q) to find the Stock Conversion Suggestions page.

- Select the desired worksheet in the Name field. If no worksheet exists yet, you can create a new one using the selection field.

- Click on Calculate Suggestions in the menu bar of the worksheet.

- In the Options FastTab, specify the Start Date from which stock movement analysis should be taken into account. The start date does not define the beginning of the period but rather the end point of the analysis. From this date, the system retrospectively analyzes the period defined in the Setting up Stock Conversion Templates section.

- Activate the Use Location Aggregation toggle switch if the demand is to be aggregated across multiple locations within a group. This ensures that uniform stock conversion suggestions are created under the main location of each group. Define the location filter as described in the next step. For more information about location aggregation, click here.

- In the Filter: Stockkeeping Unit FastTab, you can set additional stocking filters. This allows the stock conversion to be performed specifically for a certain location, stock conversion code or stocking template by entering a value in the corresponding fields.

- Additionally, you can set filters for items in the Filter: Item FastTab. This enables you to perform stock conversion suggestions for a specific item, manufacturer code, item category code or inventory posting group by entering a value in the relevant fields.

- Check all information and click OK to calculate the stock conversion suggestion lines.

- Check the values in the worksheet lines.

- To post the stock conversion for the lines and execute the dynamic stocking, click Carry Out Suggestions in the menu bar.

- A dialog window confirms that the process has been completed. Click OK.

You have successfully executed the stock conversion suggestion worksheet. The dynamic stocking process is complete.